Trinidad and Tobago can manufacture more of its own clothing

Most of the clothing used by the workforce of TT can be manufactured here, once training is provided and the basic materials imported, according to stakeholders. They also said there would need to be a rethink of how profits are distributed.

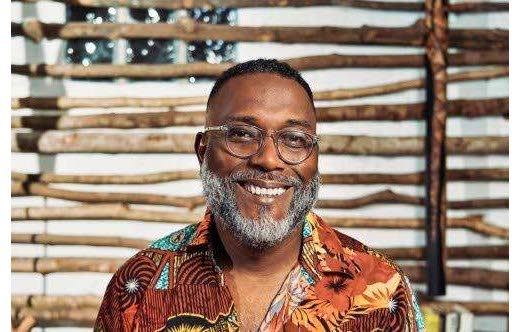

Lazuri Apparel CEO Roger Roach said there is great local demand for the workwear his company makes, including polo shirts, dress shirts and industrial workwear. The company also does printing and embroidery.

“I think there’s a lot of potential in the local sewing industry. There’s a lot of demand from where we sit for locally manufactured clothing. We export about 30 per cent of our product. So from a demand point of view, we get a lot of local demand and a lot of local support.

"I don’t think TT could manufacture all the clothing it needs, but certainly clothing required by businesses – whether it’s corporate, whether it’s industrial workwear –TT could certainly make all those things.”

He said a major impediment to growth is a lack of availability of stitchers with factory experience, which is different from the skills of a seamstress or tailor. He said the company would be interested in partnering with state agencies to offer training in this skill.

“We would be happy to work with the National Training Agency or YTEPP or Servol, any one of those institutions, to develop an organised training programme, with support from the government or the requisite state agency, and utilise our own business to do apprenticeship programme.

“If we’re serious about growing the garment industry, we need to be serious about having more people trained to sew.

"And this is different from fashion design, which UTT is doing. We’re talking about garment construction and sewing-machine operators, who will operate these machines and function in a factory environment. We’d be prepared to work with any state agency to help move that process forward.”

Roach said his company’s factory has 80 machines, but only enough staff to work on 60 of them. He said the company also just got another container-load of machines, and would be looking for 20 experienced people to man them.

“If we don’t get the experienced people, we’re willing to train people. Most of the times our machines are free on evenings and weekends. Or even in between our operations we will take on some apprentices and we’re willing to integrate them into the system, teach more people to sew and bring them in.

"If we get the support from the state – because they already have the classroom type programme, it’s structured, it’s organised – we’d be willing to play our role to assist in growing the industry.”

The Cloth founder Robert Young said while more clothing can be produced locally, the structure of ownership has to be revamped so that people are willing to work in a factory setting.

“There are many skilled people who can sew, who have decades of sewing technology that they embody. But they are now doing that for themselves and not working for a factory. There are existing factories that are having difficulty in getting highly skilled workers at the rates that they pay them.

"My suggestion, and it’s always been my belief, is that it has to be owned by the worker. There’s supposed to be some kind of facilitation to setting up a co-operative that supports workers in owning the factory and using that as a model for more than one to exist, that can do from patternmaking, sample making, to techpacks to getting items made for production, and we could fulfil a need.”

He said the same problem of having highly skilled workers working for someone else is being faced in Guadeloupe, Dominica, St Vincent, Grenada and Jamaica.

“The worker, the skilled person, the tailor, can work on their own to make one dress for $800, so why would they come into a factory and work for $300-$400 a day? But if they own the means of production, they might be more willing.

"It sounds like some Marxist socialist solution, but it’s not, it’s a human solution, using our ancestral base as an answer. Before we got tricked into indentureship and earning a wage, the Haitian Revolution, the emancipation, has always been about trying to get a better condition for people who live in the region, from the indigenous to the Africans to the Indians, and that is a solution to getting a better work situation and environment for ownership of a business. Because why should I own my business and other people can’t, who may have more skills than me?”

He said this method would also lend to the passing-down of knowledge to young people and future generations.

“The younger people will be interested, because they get to own a piece of the lot rather than getting a wage, and I think everybody understands that, even if they say they don’t understand it. You can look at it from the ancestral space of: what would my ancestors want to exist for their people now? The same minimum-wage situation, or something better?"Ownership has been a challenge, and the facilitation of that has been hindered, misunderstood and blocked.”

UTT lecturer at the Caribbean Academy of Fashion and Design James Hackett said the sewing industry in TT is vibrant, with several primarily women-owned groups providing services for a larger creative industry, including fashion.

He said many times people associate fashion design with sewing, but while sewing is a technical course of study for the programme taught at UWI, fashion design encompasses a much broader range of skills.

“There is usually a mix of folks who want to sew their own work and others who would prefer to work with a team where they do not have to focus on sewing.”

Hackett has a creative company, Lush Kingdom, which focuses on illustration, print and pattern design. He creates new inspired pieces of apparel, home and décor and creative branding services for the wider creative community, and recently began creating personalised patterns on cloth for customers.

He prints digitally on fabrics, as do other companies locally.

“The material is usually provided by the printer and you specify what you want done. Fabric printing is only one aspect of what may be needed to address creating content locally. We need to address all aspects of what makes an industry work, and I’m sure there are several papers on what the questions are that we need to ask and answer at this point.

“I think it’s feasible for local designers to go to mass market, but it would take a lot of work to get there. We do have local shops operating, and some are quietly successful.

"I think once we address ease of doing business in a serious way locally, that may alleviate some of the issues that are there.”

Caribbean Yard Campus co-ordinator Rawle Gibbons said he did not think TT could go back to manufacturing its clothing in the way it did in the 80s and 90s, when there were textile mills in the country, but the process could evolve.

“We had a shirt factory – cloth was coming from somewhere else and we were manufacturing – but those factories are no longer there.

"People have imported a lot, and it’s so much cheaper.

"In TT there’s also all the labour issues and so on, and necessarily so.

"But this is the ground we have, and I think we need to find the way to use the materials we have, and whatever basic materials have got to be imported, we import –but to build on those things and create the product out of them.

"That’s an easy fix, you develop the policies, you train the people as they’re doing now with the private sector in terms of stitching and so on, and you make it possible for them to do ease of business, for them to be able to grow their products, to market their products, and export them.

"That’s where the state comes in, making the policy and setting the infrastructure really for these productions to happen.”

Comments

"Trinidad and Tobago can manufacture more of its own clothing"