New Gen looks to hydrogen to power the next generation

TT was once a first mover in the oil and gas industry in the Caribbean, being, up until the early 2000s, one of three countries in the Caribbean that had oil and gas reserves.

Now, with the demand for these hydrocarbons being believed to have reached its peak, the world is searching for new, cleaner forms of energy that would balance the needs of progress, the necessity for energy and the need to preserve our environment.

TT is once again poised to take advantage of a growing industry that could change the face of the energy sector for decades to come. That industry is hydrogen.

Hydrogen, the most abundant element in the universe, can be used to not only store, but generate energy that could power homes, cars, and even your cellphone. But for TT, the production of hydrogen in a large enough scale could spark a billion-dollar industry which could have our petrochemical plants running at its optimum capacity, something that had not happened for years, and have us once again as the first of many in the world on the way to decarbonising the world’s energy sector.

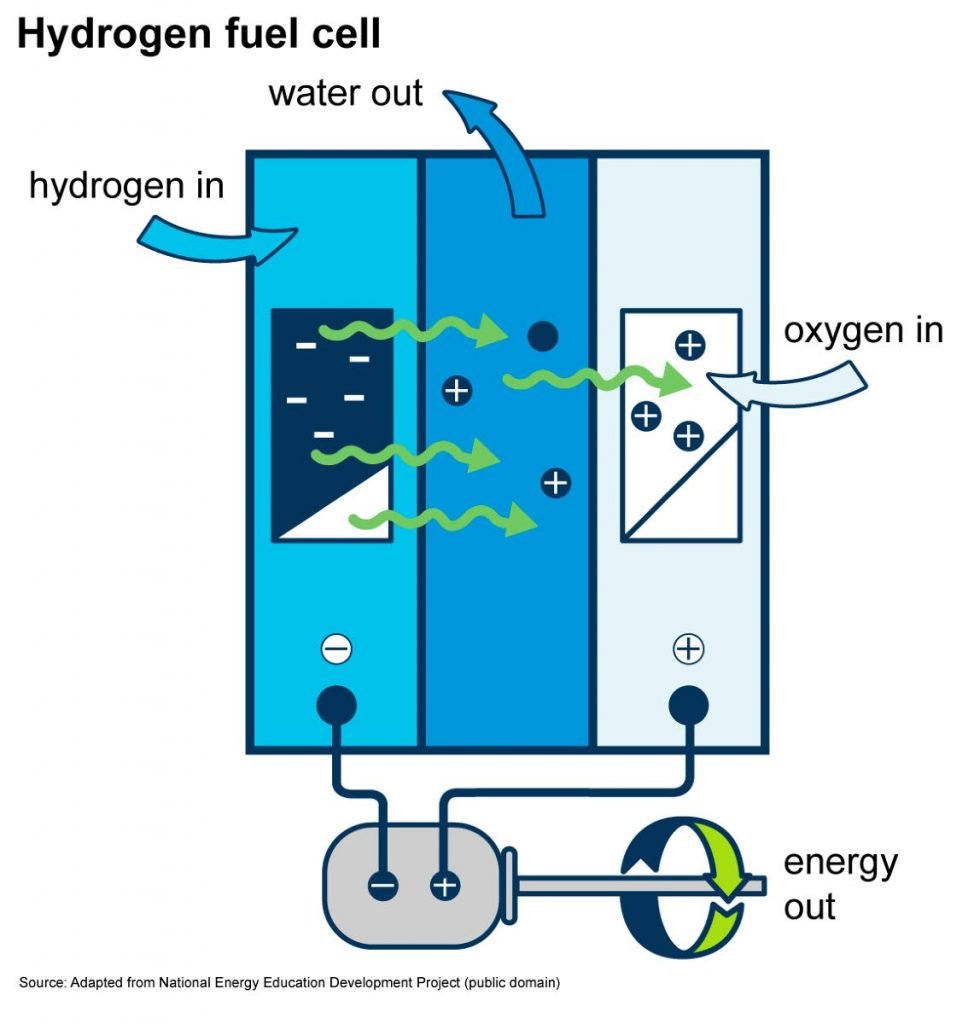

According to the US Department of Energy, hydrogen is a clean fuel that produces water as a by-product. Hydrogen can be produced from a variety of domestic resources, including natural gas, nuclear power, biomass and renewable power like solar and wind. The most common methods to create hydrogen fuel today are natural gas reforming (a thermal process), and electrolysis.

Energy companies and players in the hydrocarbon and energy sector gathered at a workshop at the Hyatt Regency, Port of Spain last Wednesday, the final day of the TT Energy Chamber's 2020 Energy Conference to workshop ways to take advantage of this new trend in clean energy. The minds behind project management company Kenesjay Ltd joined forces with Siemens, a global powerhouse and one of the leading producers of energy-efficient and resource-saving technology, to offer the solution to a question that some did not know they had – how to tap in to the clean energy sector.

Philip Julien, managing director of Kenesjay Systems Ltd introduced stakeholders at the workshop to New Gen, a company which aims to pioneer TT’s drive into clean energy using hydrogen

Their plan is simple. They intend to build a hydrogen plant that would use an electrolyser from Siemens and take the materials we already have to make hydrogen.

Electrolysis is a process that decomposes chemicals by passing an electric current through a liquid or solution containing ions (atoms or molecules with a net electric charge due to the loss or gain of one or more electrons). This process, when applied to water, separates it into parts of hydrogen and oxygen.

That hydrogen can be used in the process of making ammonia and used as a substitute for natural gas as a feedstock in making methanol.

Energy consultant Mushtaq Mohammed, a director at New Gen, said the country could benefit from the electrolyser technology, but it was the structure of TT's industrial sector which gives the country a strategic competitive advantage.

“We see that there is power that is available to us, and water that we could use to produce clean hydrogen,” said Mohammed. “We have great competence in constructing plants. So there are a few things working for us which allows us to be part of a decarbonised world.”

Mohammed said TT also has the benefit of having its industrial plants very close to each other.

Methanol Holdings (MHTL), on Atlantic Avenue, Pt Lisas relies on a natural gas feedstock to provide a catalyst for the creation of methanol. Natural gas is also the catalyst in the making of ammonia, which is used for fertiliser. All of the 11 ammonia plants in an around the Point Lisas area can benefit from having a substitute catalyst for the making of these chemicals.

Minister of Public Utilities Robert Le Hunte in his contribution pointed out that almost 38 per cent of our natural gas is used as a feedstock in the production of methanol and ammonia. If that were to be replaced with a cleaner chemical, the result will boil down to simple math.

Less natural gas used in making these chemicals would mean less carbon emissions. The less natural gas used to make these chemicals would also mean more natural gas for export.

“The technology is not new. But advances by Siemens has made it scalable to the point where we could produce volumes which would allow us to inject it into chemical plants to produce methanol and ammonia.”

Philip Julien, managing director of Kenesjay, said introduction of hydrogen fuel to the industry would not only benefit the economy and environment on a large scale, but it would also provide a range of opportunities for almost everyone.

“Our feasibility study gave us a fairly close assessment of the amount of hydrogen we can produce and it is about 25 per cent of the typical ammonia plant. We have two universities that can innovate the heck out of it. It is a tremendous opportunity for our educational institutions to innovate and educate our people in brand new career opportunities.”

In terms of initial contribution to the economy, the factory alone would require construction workers and even after it was built people would be called upon to assist in bringing TT into what Le Hunte described as a US$150 billion industry.

“It is a new energy for a new generation,” Julien said, who is also the founder and chairman emeritus of the Heroes Foundation. “And having just come from a room of about 400 secondary school students all talking in unison about the importance of us looking after our carbon emissions, hydrogen is truly a new energy for a new generation.”

Comments

"New Gen looks to hydrogen to power the next generation"